Research

My research group studies robot learning and computer vision.

My research group studies robot learning and computer vision.

Research Interests

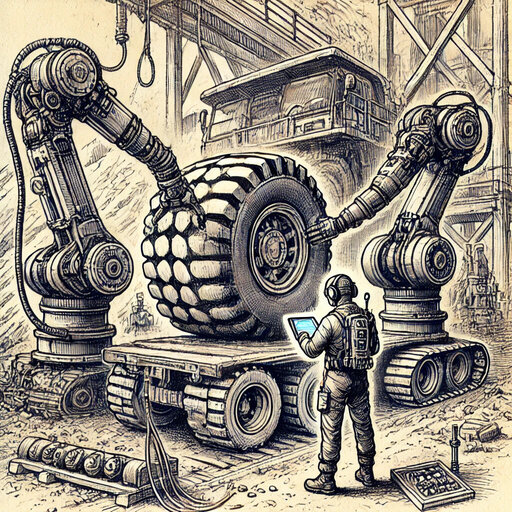

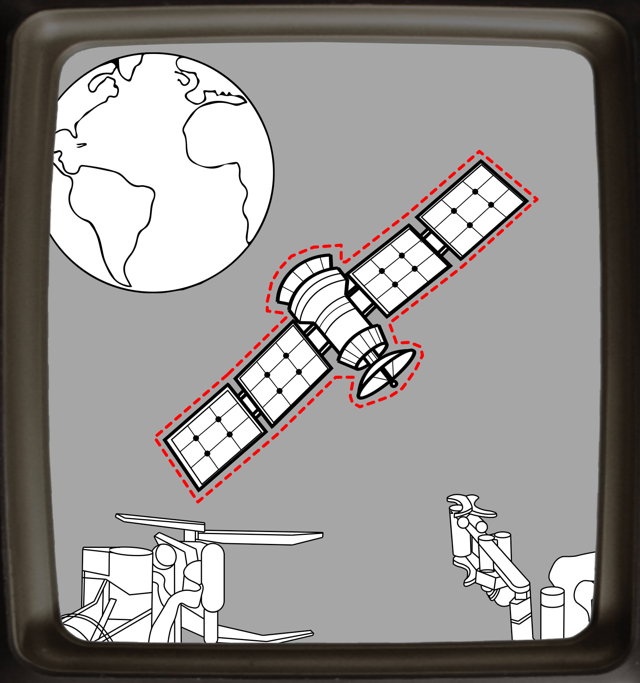

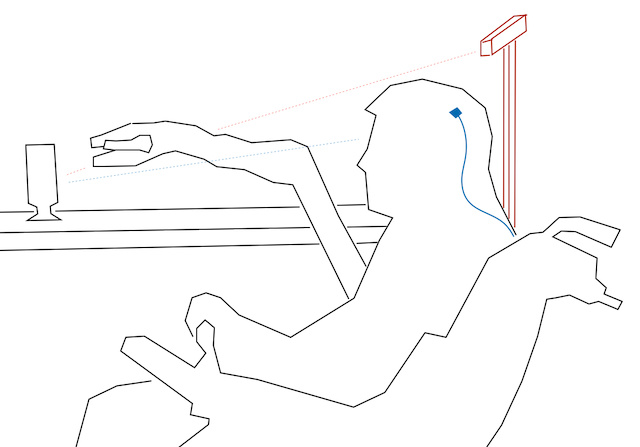

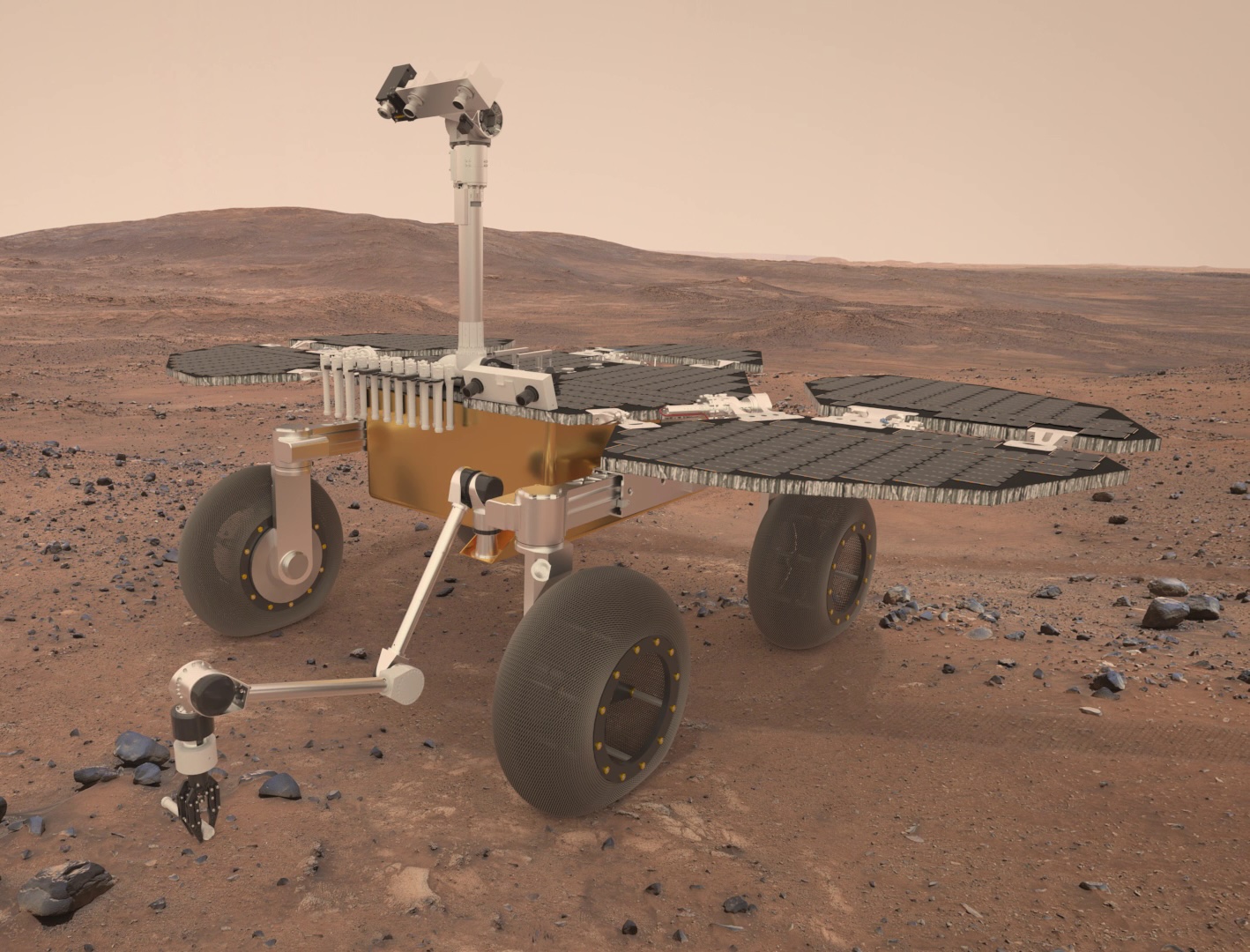

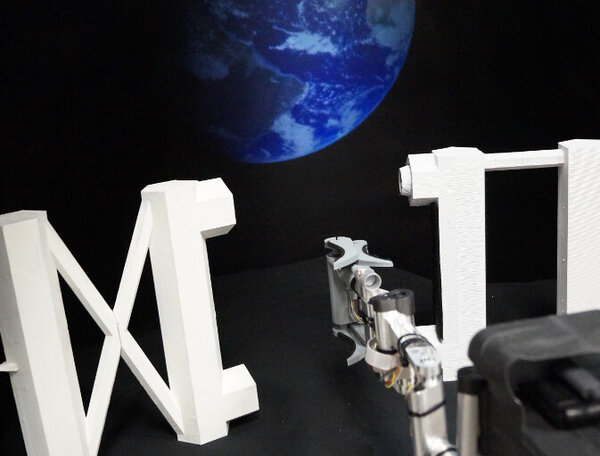

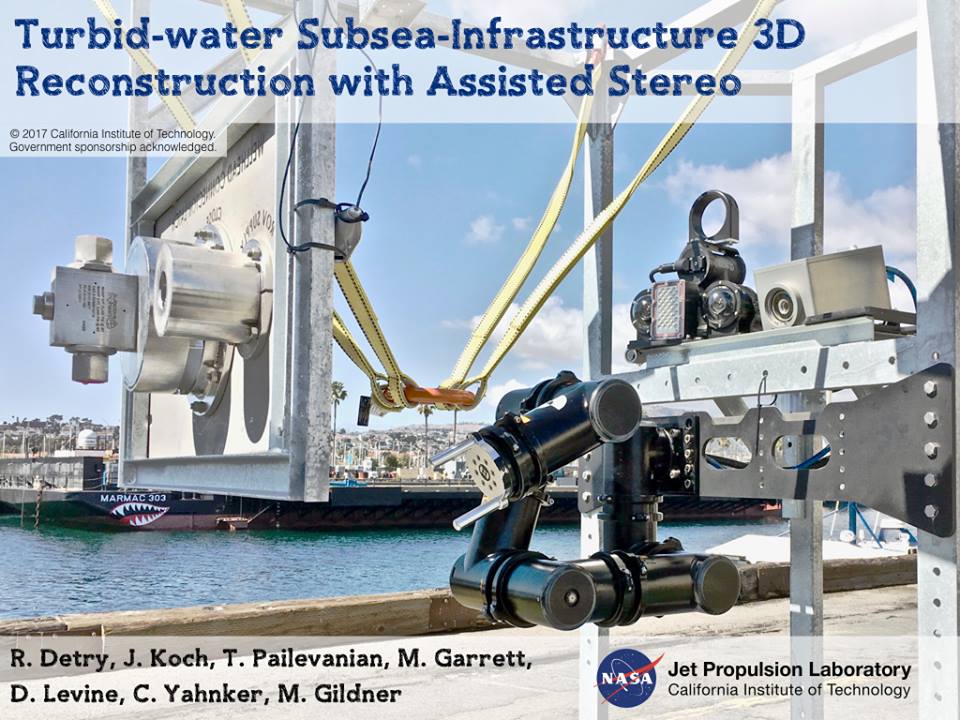

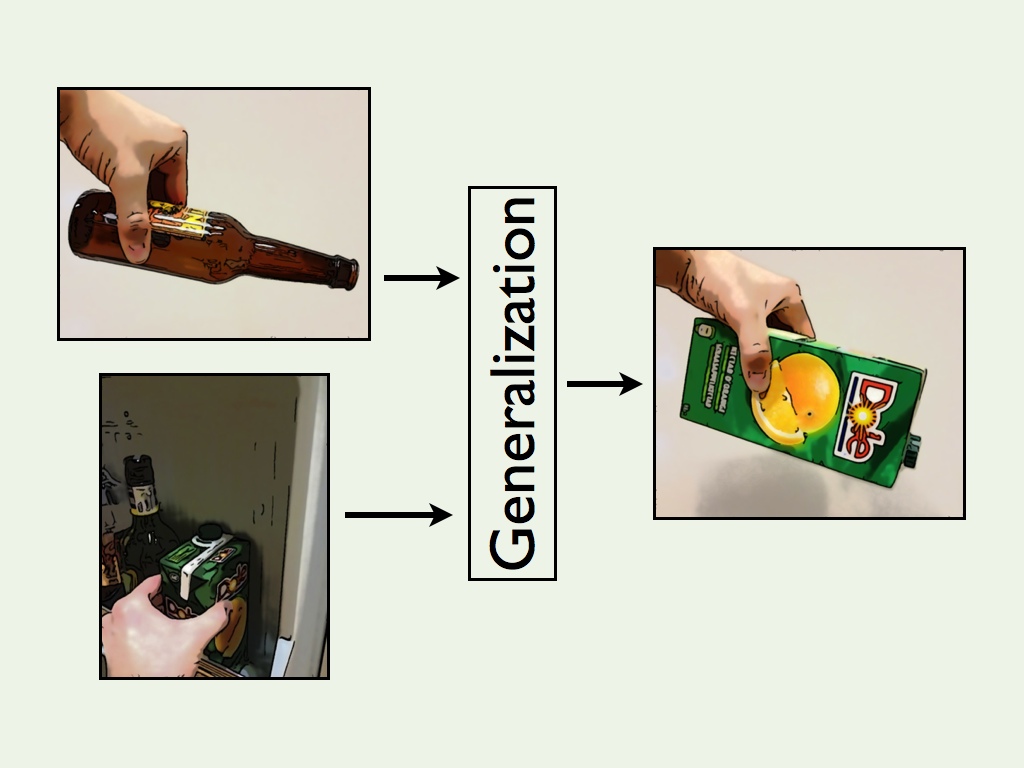

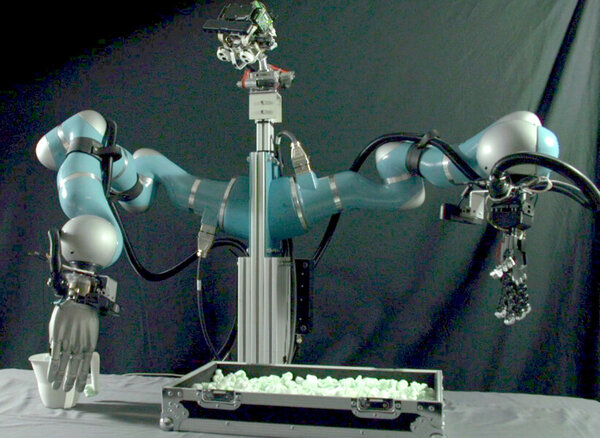

My core research interest is in adaptive robotics, with a special interest in space applications. I develop robotic systems that cope with the complexity of our world by using cameras and other sensors to observe and parse their surroundings and learn to adjust their behavior accordingly. My research aims to bring autonomous robotic assistance to sectors where working conditions are dangerous or impractical for humans. This includes space robotics and planetary exploration, robotic assistance for people suffering from limited mobility, as well as manufacturing, construction, or agriculture. My work is at the intersection of robotics and machine learning, which is reflected in my dual appointment within KU Leuven’s departments of electrical and mechanical engineering.

My work focuses on casting robotics problems to a form that is catalytic to data-driven modeling. Much of the creativity involved here goes into crafting… [show more]

Keywords: Robotics, computer vision, robot learning, space robotics.

Projects

Ph.D. Students

Current students:

- Alessandra Miuccio (Personal Webpage)

- Yutong Hu (Personal Webpage)

- Ze Fu

- Elias De Smijter

- Zhongxi Li

- Yurui Du

- Pinhao Song

- Antoine Legrand

- Louis Hanut

Past students:

- Deniz Soysal

- Joseph Bowkett (informal co-supervision with Joel Burdick, Caltech)

- Emil Hyttinen (co-supervision with Danica Kragic, KTH)

- Martin Hjelm (informal co-supervision with Danica Kragic, KTH)

- Alexander Rietzler (informal co-supervision with Justus Piater, UIBK)

- Ashley Liddiard (informal co-supervision with Bryan Tripp, UWaterloo)

- Yasemin Bekiroglu (informal co-supervision with Danica Kragic, KTH)

Software

My group’s software is available on our GitLab portal. Older software from my Ph.D. and postdoc is freely available on this page.

Jobs

See this page.

Videos

See this page.

Events

See this page.